Speedy wind turbine maintenance bot could cut downtime

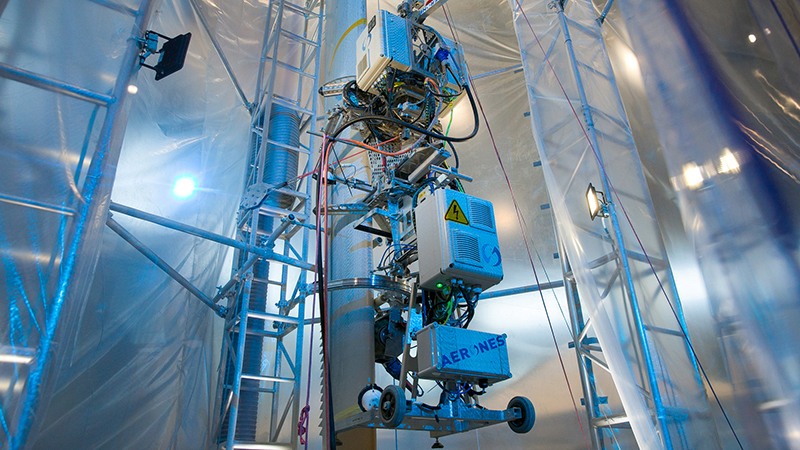

The Aerones wind turbine blade maintenance and repair robot, as seen at a demonstration in Riga

The Aerones wind turbine blade maintenance and repair robot, as seen at a demonstration in Riga

A new robot can maintain and repair wind turbine blades five-times faster than human workers, its developers have claimed.

Aimed at minimising turbine downtime and preventing costly repairs, the robot from Latvian start-up Aerones was unveiled today (24 January) in a demonstration in Riga.

The modular machine uses attachments to perform different tasks, the company said, including refinishing blades' new coatings. It can perform maintenance and repair for early stages of leading-edge erosion, halting its progress.

The wind turbine maintenance and repair market was valued at $36.27bn in 2022, and is expected to grow to $63.82bn by 2029. Aerones said current methods are “slow and costly”, however, with manual rope access technicians facing an injury rate of 0.64 per 1,000. The robot can reportedly work in wind speeds up to 15m/s, while technicians are able to work in up to 9m/s.

“Global energy demand in the next 20-30 years will double, and the steepest growth will be in the near future. To support the industry's growth, our goal is to offer a robotised system that can repair wind turbine blades at any moment when it's necessary,” said Aerones co-founder Dainis Kruze.

“We continue to work towards making the robot as resilient as possible to various external conditions, which is why we've tested our system in extreme heat, humidity, and wind. Our ultimate goal is to create a product where wind turbines would only have to be stopped for a short time, or not at all, in order to be repaired.”

The modular system can tackle tasks including cleaning, surface preparation, primer application, leading-edge filler application and protection coating.

Aerones has also implemented turbine and erosion modelling using digital-twin technology, replicating and monitoring the wind turbine in a digital environment.

The company’s previous robot, which was not modular, has already been used by servicing teams around the world.

Want the best engineering stories delivered straight to your inbox? The Professional Engineering newsletter gives you vital updates on the most cutting-edge engineering and exciting new job opportunities. To sign up, click here.

Content published by Professional Engineering does not necessarily represent the views of the Institution of Mechanical Engineers.